The unassuming Boise woman with the critical job that is ‘necessary for our entire world to exist’

When Brienna Hall joined ASML last year as a customer support engineer – a role she jokingly calls a ‘fancy mechanic’ – she had no idea how essential her work would be.

And to most, the 29-year-old’s work for one of the world’s most important tech giants remains a closely guarded secret.

At the chip factory in Boise, Idaho, Hall dons a cleanroom bunny suit and works on an extraordinary machine in an environment 100 times cleaner than a hospital operating room.

Her job is to maintain the extreme ultraviolet (EUV) lithography machine, an advanced piece of technology responsible for producing the world’s most advanced microchips.

These machines, which cost $170 to $370 million each, are built using advanced technology that was once thought impossible.

They are vital to modern life, powering devices such as phones, computers, TVs and even cars.

“I thought I had the coolest job ever,” Hall told the newspaper Wall Street Journal. “I haven’t considered that this job is necessary for our entire world to exist as it does today.”

ASML, the Dutch company that produces all EUV machines, is the backbone of the chip industry.

Brienna Hall works as a customer support engineer at ASML, a vital company that most people don’t know about. She maintains EUV lithography machines, crucial for the production of advanced microchips

Hall’s work ensures these machines operate flawlessly, enabling the production of semiconductors that power devices such as telephones, computers, TVs and even cars.

Hall, based at Micron Technology’s Boise factory, ensures these machines operate flawlessly, enabling the production of semiconductors that power the modern world.

EUV machines, a scientific marvel, started 40 years ago in a small, leaky shed in the Netherlands with the founding of ASML.

At the time, using extreme ultraviolet light to print chips seemed impossible, requiring decades of effort, massive funding and groundbreaking science.

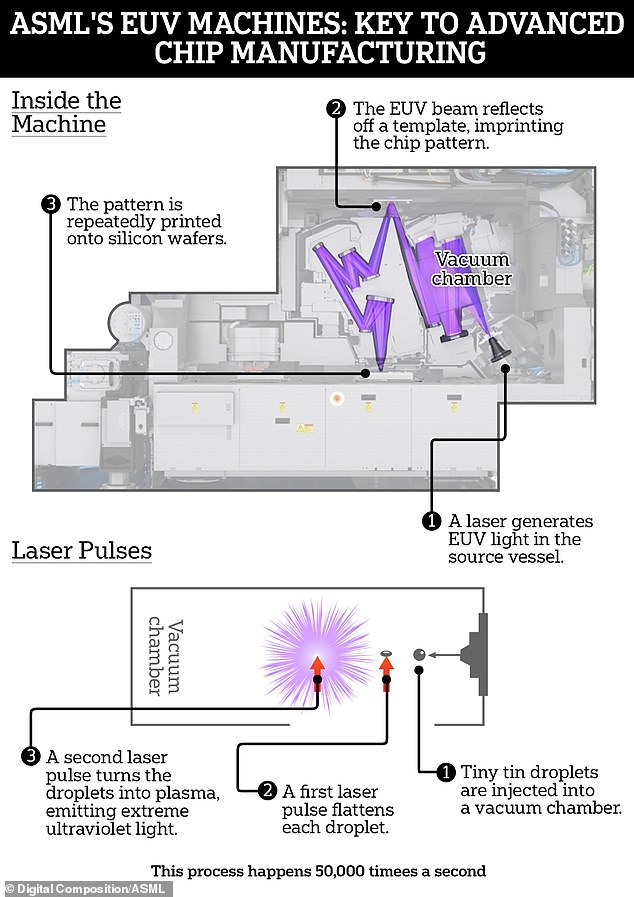

EUV technology involves vaporizing molten tin droplets and using double laser pulses – 50,000 times per second – to flatten them and then explode them into plasma, emitting EUV light.

This light is collected by ultra-smooth mirrors and focused to etch billions of microscopic transistor patterns onto silicon wafers.

The current wavelength of 13.5 nanometers enables chip resolutions that are 10,000 times finer than that of human hair.

Developing EUV lithography took decades. ASML delivered its first EUV system in 2010, its 100th in 2020, and shipped 42 machines last year.

Despite their importance, only six companies own these machines, while countless others are indirectly dependent on them.

ASML’s technology is essential for products like iPhones and AI data centers, with companies like Apple and Nvidia relying on its precision through manufacturers like TSMC.

Maintaining these $370 million worth of machines is critical. ASML employs 10,000 customer support technicians worldwide to ensure they are always operational.

Disruptions can result from unexpected factors, such as earthquakes – or even methane gas from dairy farms, as Intel once discovered.

Hall and her colleagues are ASML’s frontline troops who keep these indispensable machines operational and drive the modern technology world forward.

ASML is the only company that produces EUV machines, and they are essential to the modern technology industry

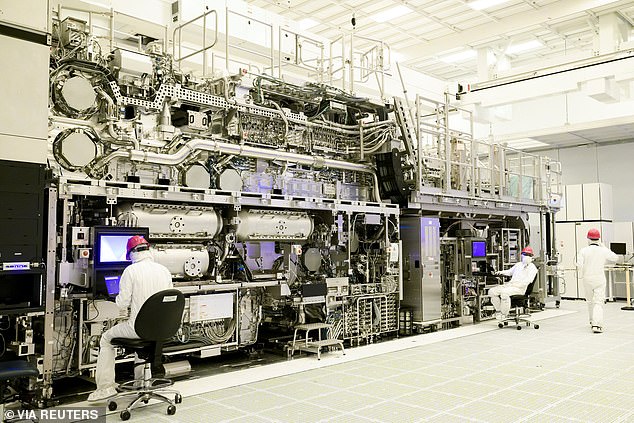

Pictured: Workers are seen in front of a ‘High NA EUV’ lithography system at an Intel factory in Hillsboro, Oregon, USA.

Signs of Brienna Hall’s future success at ASML were visible long before she joined the company.

Hall, now 29, grew up in Seattle and was a Boy Scout who loved perfecting knots. She later became president of the rocket club at Edmonds College while earning her associate degree.

At Washington State University, she studied materials science and engineering, transcribed notes for a textbook on quantum mechanics, and spent her free time quilting and putting together complex jigsaw puzzles.

She also planned camping trips, despite not liking camping herself.

These experiences prepared her for the meticulous, problem-solving nature of working on a machine with more than 100,000 parts.

“You’re always solving problems,” Alex Jordan, another ASML engineer, told the Journal. ‘How can I be more efficient? Where can I optimize?’

ASML is looking for disciplined, detail-oriented engineers for customer support roles, and Hall’s technical skills and temperament were a perfect fit.

When her professor heard that a semiconductor company was hiring, Hall submitted her resume and soon received an email from ASML. The promise of travel and hands-on work was enough to seal the deal.

Her first big trip was a month in Taiwan at the ASML training center, where she learned the ins and outs of the EUV machine. She honed her skills by taking months of Fab Ready 2 courses and traveling to Taiwan, San Diego and Germany.

It took almost a year of internship before Hall was cleared to work independently on the EUV machine.

Each part, such as the scanner and laser, has its own quirks. At Micron’s Boise plant, the scanner has been nicknamed Monica, after the “neat freak” character from the sitcom Friends — “because everything has to be perfect,” Hall said.

Pictured: the process of ultraviolet lithography

When she’s not traveling to different continents, she is based at ASML’s office near Micron’s campus, working 12-hour shifts from 6 a.m. to 6 p.m.

Some days Hall goes straight to the factory for hands-on work. On other devices, she monitors the machine remotely from her desk, analyzing data on multiple screens.

“I’m sure the machine won’t ignite on its own,” she said.

Once she is satisfied that the system is stable, she shifts her attention to scheduling the tasks for the next “scheduled down,” a routine maintenance period designed to prevent costly, unplanned outages.

Micron’s roots run deep in Idaho. Nearly half a century ago, four entrepreneurs, including an investor who was a local potato baron, founded the company in the basement of a dental practice.

Now, with a $15 billion investment, Micron is bringing industry-leading memory manufacturing back to American soil. This new factory, which dwarfs the Empire State Building in terms of concrete foundation, will cover an area equivalent to ten football fields.

Adjacent to this construction site is Micron’s existing research facility, home to a 300,000-pound behemoth – an EUV machine flown in from the Netherlands on three separate 747 freighters.

Brienna Hall admits that she cannot monitor the EUV machine at the factory for more than a few days, fascinated by its capabilities.

“By then I’ll be itching and have a reason to go in,” she said.

Upon entering the cleanroom, Hall undergoes a meticulous transformation. Covered from head to toe, a precaution against even the smallest dust particle that could wreak havoc on the delicate machinery.

To minimize disruptions, she limits her water intake and forgoes coffee altogether.

Inside the fab, under the dim yellow lights, it is hot, loud and disorienting, but that doesn’t bother her.

“When I work on the tool and solve a problem, everything else just goes quiet,” she explains. “It’s all about zeroing in and getting that one thing done. There’s nothing better than fixing it.”

During one visit, Hall noticed a problem with the water line: a minor deformity in a hose that could escalate into a major problem.

It took almost a year of internship before Hall was cleared to work independently on the EUV machine

Some days Hall goes straight to the factory for hands-on work. On other devices, she monitors the machine remotely from her desk, analyzing data on multiple screens.

After receiving permission, she grabbed two orange buckets from Home Depot, drained the line, replaced the Teflon tubing and installed thermal sensors to monitor it.

The solution was simple, but essential to avoid downtime of the multi-million dollar machine.

“It’s not glamorous,” Hall said, “but I take pride in keeping my machines running for our customers.”