Step inside Jaguar Land Rover’s new EV test facility in Britain’s Motor City

These are the first images of Jaguar Land Rover’s new Future Energy Lab – a state-of-the-art electric vehicle testing site in Coventry that will secure 200 future jobs and create 150 new jobs in the region.

The facility opened on Monday and is part of the British manufacturer’s moves to launch nine pure-electric luxury cars by 2030 in a bid to catch up with rivals such as Tesla.

Located in the West Midlands – historically the heart of the British car industry, where Coventry has been dubbed the British Motor City – it cost £250m and will enable ‘rapid testing of electric vehicles’, in a bid to accelerate JLR’s electrification timeline.

Step inside JLR’s new EV testing facility in the heart of the UK car industry: the company’s new £250m Future Energy Lab will enable ‘rapid testing of electric vehicles’ in a bid to accelerate the company’s electrification timeline

The new 30,000 square meter facility is located at JLR’s Whitley Engineering Center and features more than £40 million of technological innovations, including electrical test rigs, electric drive unit production and test cells for EV systems.

This includes a range of extreme weather climate chambers, capable of simulating the harshest conditions – from -40°C to 55°C – to ensure JLR’s electric cars of the future can withstand all climates.

The facility is part of JLR’s wider £15 billion investment to electrify its luxury brands over the next five years.

This includes launching the first all-electric Range Rover by the end of next year and transforming Jaguar into an electric-only premium car brand by 2026.

The facility opened on Monday and is part of the British manufacturer’s moves to launch nine pure-electric luxury cars by 2030 in a bid to catch up with rivals such as Tesla.

From left to right: Oliver Boakes, Chief Engineer at JLR, Mayor of the West Midlands Andy Street, and JLR Managing Director Thomas Müller at the opening of the Future Energy Lab

The new 323,000 sq ft facility is located at JLR’s Whitley Engineering Center and features more than £40 million of equipment. Mayor Andy Street takes a closer look at one of the new test setups

JLR hopes the site will enable sustainable scale-up of the next generation of EVs, reducing the need to transport cars to other global testing facilities during the development process.

“By increasing its on-site EV testing capacity, JLR is minimizing the costs and emissions associated with sending prototype cars around the world for test assessments,” the brand says.

JLR confirmed that more than 200 EV engineers are already working at the factory.

A further 150 jobs will be created in the coming months, providing a ‘significant employment boost to the regional economy’, the report said.

JLR plans a further £22m of investment next year as it continues to improve its Coventry site.

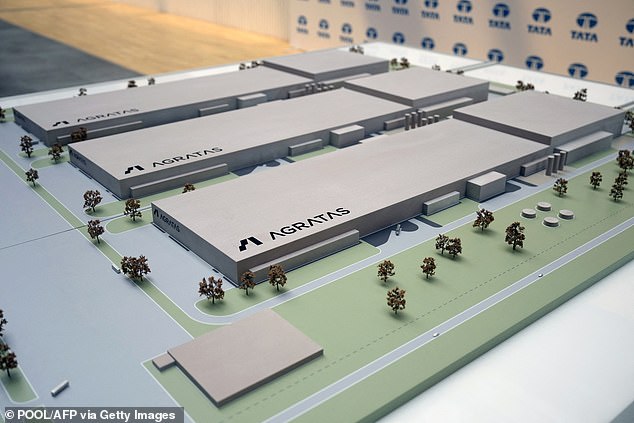

It comes in the wake of JLR’s parent company Tata confirming in July that it will build a massive £4 billion ‘gigafactory’ in Somerset to produce batteries to power these future EV models, including from around 2026, when the facility must be put into use.

By producing its own batteries, JLR can avoid the post-Brexit export tariffs that will be imposed on EU and UK carmakers from next year, making the average EV £3,400 more expensive than it is today.

From January 1, ‘Rule of Origin’ tariffs of 10 percent will be imposed on electric car exports between the UK and the EU if at least 45 percent of the value does not originate in the UK or the EU.

If introduced within weeks, manufacturers are expected to pass these higher costs on to their customers through higher prices.

With batteries being the largest cost of any electric car, it is crucial for makers to create their own manufacturing hubs domestically.

A model of JLR owner Tata’s proposed electric battery factory has been confirmed to be built in Somerset. It will cost as much as £4 billion and will be operational in 2026, the company says

The facility is part of JLR’s wider £15 billion investment to electrify its luxury brands over the next five years, including launching the first all-electric Range Rover by the end of next year and transforming Jaguar into a premium electric-only car brand . 2026

Coventry’s state-of-the-art electric vehicle testing site has secured 200 existing jobs in the sector for the future

JLR bosses say the EV testing lab will also create 150 new jobs in the region – an economic boost for the West Midlands

Commenting on the opening of the new EV testing laboratory, Thomas Mueller, executive director of product engineering at JLR, said: “Our vehicles are and will continue to be at the forefront of an all-electric automotive future.

“This facility, a core component of our Reimagine strategy, is essential for providing the advanced testing capabilities that will be vital to the performance and reliability of the modern luxury vehicles we proudly develop.”

Oliver Boakes, chief engineer responsible for powertrain development at the company, added: ‘Our operations at Whitley are at the heart of JLR – itself a leading company in the local community – so this testing facility is another jewel in the crowning our step towards a fully electric future.

“This is a remarkable investment for businesses and the local economy.”

Some links in this article may be affiliate links. If you click on it, we may earn a small commission. That helps us fund This Is Money and keep it free to use. We do not write articles to promote products. We do not allow a commercial relationship to compromise our editorial independence.