Sleeve Anchor vs. Wedge Anchor – Which One Is Right for Your Project?

When tackling a construction or home improvement project, small details can make a big difference. One such detail is the humble anchor. Anchors might be unseen once a project is complete, but they play a pivotal role in ensuring structures are secure.

If you’ve ever found yourself in an aisle full of fasteners and anchors feeling overwhelmed, you’re not alone. Today, we dive deep into two popular anchors – the sleeve anchor and the wedge anchor – to help you figure out the best fit for your next venture.

Understanding Anchors – A Brief Primer

Before we jump into the specifics of the “sleeve anchor vs wedge anchor” debate, let’s get a quick overview of anchors in general. At their core, anchors are tools designed to connect or secure one object to another, often a fixture to walls or floors. In the construction world, they’re the unseen heroes, holding our world together, quite literally.

Sleeve Anchors – Features and Benefits

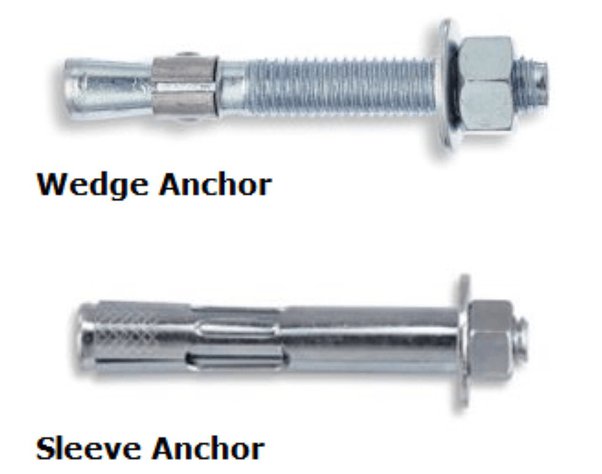

Imagine you’re setting up a wall-mounted shelf or attaching a heavy painting to a masonry wall. Here’s where sleeve anchors come into play. These anchors are made up of an outer sleeve with an internal screw mechanism. When tightened, the outer sleeve expands, providing a snug fit against the material it’s being fastened to.

Why might you consider sleeve anchors?

- Adjustability in the Hole – Once installed, you can adjust them within the hole, offering flexibility during the installation process.

- Versatility – Sleeve anchors can grip a variety of materials, from concrete and brick to block walls.

- Ease of Installation – No special tools or expertise is needed. A simple drill and the anchor kit are enough.

Wedge Anchors – Features and Benefits

For more heavy-duty tasks, especially when you’re dealing strictly with concrete, wedge anchors stand tall. These anchors consist of a straight metal rod with a small, wedge-like clip at the end. As the rod is hammered or screwed into a hole, the clip gets anchored firmly into the concrete.

What makes wedge anchors a top choice:

- Strong Holding Values – They offer a more permanent grip, making them ideal for weight-bearing installations.

- Permanent Installation – Once in place, a wedge anchor is there to stay. It’s not coming out without a fight.

- Concrete Specialty – These are the go-to anchors for concrete applications, ensuring maximum holding power.

Key Differences Between Sleeve and Wedge Anchors

The central “sleeve anchor vs. wedge anchor” debate boils down to understanding their key differences. At first glance, they might look similar, but their applications and benefits vary.

Design & Mechanism

Sleeve anchors have a two-part mechanism; an outer sleeve and an internal screw or stud. As the internal component is tightened, the sleeve expands, gripping the sides of the drilled hole. This spreading force offers a secure hold across a range of materials.

In contrast, wedge anchors function with a singular focus. They use a straight metal rod partnered with a wedge-like end. When inserted, the wedge is forced upwards as the rod is hammered or screwed down, creating a powerful, anchored bond specifically with concrete.

Material Compatibility

While both anchors are robust, their preferred materials differ. Sleeve anchors pride themselves on adaptability. Their design allows them to perform admirably in various materials, including concrete, brick, and block walls. On the other hand, wedge anchors excel exclusively in concrete. Their design, focusing on a singular wedge action, ensures they grip concrete with unparalleled strength.

Flexibility vs. Permanence

Post-installation adaptability can be a game-changer. Sleeve anchors, with their adjustable nature, offer the option to reposition or modify the installation after the fact, granting a touch of flexibility. Wedge anchors, however, commit with decisiveness. Once set, their bond is incredibly durable, making them apt for projects where longevity and unwavering strength are paramount.

Installation Depth and Hole Cleaning

The efficiency of an anchor often lies in the nuances of its installation. Sleeve anchors are somewhat forgiving, able to function even if the drilled hole contains some debris. However, wedge anchors demand a cleaner hole for optimum performance. Any debris in the drilled hole can hamper the wedge mechanism, making it essential to clear out the hole thoroughly before installation.

Factors To Consider When Choosing Between Sleeve and Wedge Anchors

When weighing up sleeve and wedge anchors, consider:

- Material of the Base Object – Concrete? Brick? Block? Identify the base material of your project.

- Project Type – For temporary structures, a sleeve anchor’s adjustability can be handy. For long-lasting fixtures, the permanence of a wedge anchor might be preferable.

- Load Requirements – Assess the weight and load the anchor will bear. Heavier loads often lean towards wedge anchors.

- Environmental Considerations – For outdoor projects, consider factors like potential corrosion from rain or coastal salt.

Tips for Proper Installation

Whichever anchor you opt for, correct installation is crucial:

- Follow Manufacturer Guidelines – Each anchor type may have specific drill bit sizes or installation depths.

- Safety First – Always wear protective gear, like goggles and gloves, during installation.

- Quality Over Quantity – It might be tempting to save a few bucks on generic anchors, but trusted brands often provide better performance and safety guarantees.

Conclusion

The small choices matter. Whether it’s sleeve or wedge anchors, understanding their nuances can ensure your projects stand strong for years to come. As you embark on your next construction or DIY endeavor, may your choices be well-informed and your structures ever-sturdy!