One Brit dead and dozens sick in ‘superbug’ outbreak linked to contaminated eye drops

One Briton has died and dozens of others have been sickened by a ‘superbug’ outbreak linked to contaminated eye drops.

Health chiefs have traced the crisis to three separate medical drops produced in India for dry eye patients.

They were all thought to carry an antibiotic-resistant bacteria that can be fatal to immunocompromised patients.

Bosses at the UK Health Security Agency (UKHSA) believe the outbreak is now over, with its worst impact occurring last autumn when the products were originally recalled.

No details have been released about the deceased patient.

Brand names linked to the outbreak included several lots of eye drops AaCarb, Aacomer and Puroptics

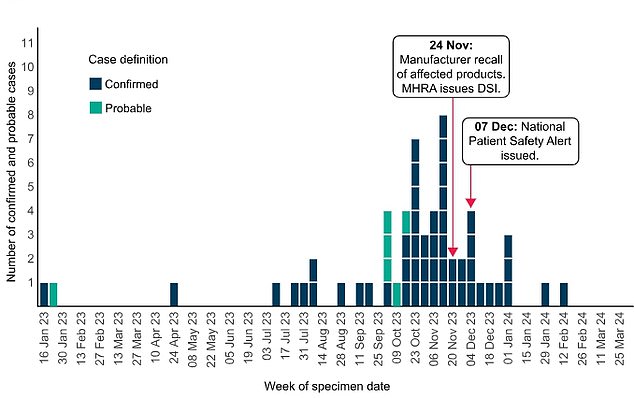

UKHSA said that as of March 21, officials had confirmed 52 confirmed cases linked to use of the eye drops in Britain, as well as six additional ‘probable’ cases. This graph shows the timeline of the outbreak in Britain

Burkholderia cenocepacia – a type of bacteria that is naturally resistant to the antibiotics normally used to treat such infections – was cited as a contributing factor to their deaths.

The drugs are manufactured by Indiana Ophthalmics, a company based in India.

Several batches of AaCarb, Aacomer and Puroptics brand carbomer eye gels were affected.

Such products are usually given to patients who suffer from dry eyes and can be purchased online for as little as £4.50.

UKHSA said officials had confirmed 52 confirmed cases linked to use of the eye drops in Britain as of March 21.

A further six cases were classified as ‘probable’.

The youngest sick patient was a baby, while the oldest was 91.

The vast majority were already in hospital and being treated for another problem when they were given the eye drops by staff who were unaware they were using a contaminated product.

The cases were assessed by UKHSA as involving ‘clinically significant infections’ caused by Burkholderia cenocepacia.

Eleven suffered from eye infections. Some developed ulcers in their eyeballs, others developed conjunctivitis and a serious ‘deep tissue infection’.

Nine patients developed respiratory infections and four others had blood poisoning.

Most cases were detected between October and December, but one case occurred as early as January 2023.

Only after a surge in cases were officials able to link the outbreak to the eye drops.

This led to Indiana Ophthalmics issuing a voluntary recall for their three brands of carbomer eye gel in November.

UKHSA also issued a national patient safety alert in December advising all clinicians in the NHS to avoid the use of carbomer eye gels in high-risk patients, such as those undergoing chemotherapy.

In an update yesterday, UKHSA said the outbreak has now slowed, with the last case noted in February.

As such, they withdrew their advice on limiting the use of carbomer eye gel.

But they added that officials will continue to monitor for new infections.

This is not the first time that Indian eye drop makers have been linked to infections.

In April last year, there was a wave of eye infections in the US that caused death and blindness, linked to products made by Global Pharma Healthcare in India.

The drugs involved in the outbreak were manufactured by Indiana Ophthalmics, an eye medicine company based in India.

U.S. inspectors who visited the company’s factory in Tamil Nadu state found dirty equipment and clothing, missing safety measures and procedures and dozens of other problems.

In a document the U.S. Food and Drug Administration wrote, they found poor cleaning throughout the plant, as well as significant gaps in written procedures and training for employees.

Surfaces that came into contact with packaging “had not been cleaned, sanitized, decontaminated or sterilized” and there were gaps or discrepancies in data related to how key machines and areas were cleaned.

Surfaces were not easy to clean as one room had ‘soft, rough and cracked caulk, protruding nails and nail holes’ in the walls.

The company also did not track or have rules about how often sterile coveralls could be reused after washing in the company’s cleanroom – where the eye drops are manufactured.

An inspector also noticed a “black, brown, greasy deposit” on part of one of the company’s machines used to bottle the product.

Global Pharma Healthcare Pvt Ltd was found to have skipped important tests to check whether the products were sterile.

The company also failed to verify the ingredients it used to make the products, relying only on what the supplier said.