Build-your-own-chip startup wants everyone to design and fab their own processor via a simple UI – but Nvidia, Intel et al needn’t worry for now

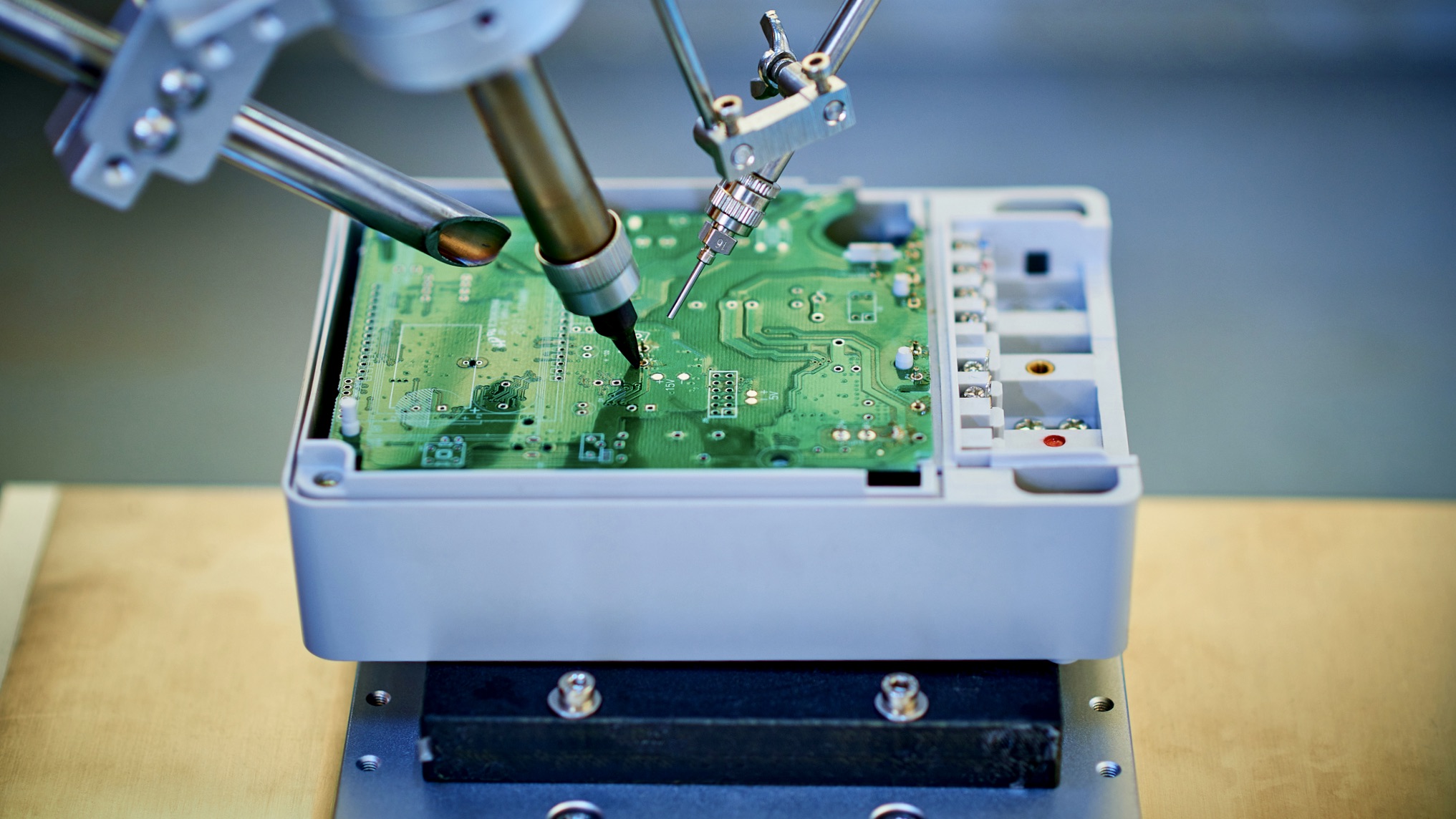

Chip design, especially building custom application-specific integrated circuits (ASICs), typically costs more than $100 million and takes about three years to go from concept to production. But Zero ASIC automates chip design using a no-code approach.

The company has revealed that it will offer customers early access to its ChipMaker platform, which it says can quickly assemble custom multi-chiplet system-in-package (SiP) units without the traditional production burden.

Zero ASIC aims to democratize access chip manufacturing and make it more viable for businesses by offering them a simplified chiplet-based design process. This means customers can build, test and customize their designs before ordering devices, with cloud-based Field Programmable Gate Arrays (FPGAs) allowing them to deploy RTL source code.

Building a chip, one eBrick at a time

“To build the next wave of world-changing silicon devices, we need to lower the barrier to ASICs by orders of magnitude,” said Zero ASIC CEO and Founder Andreas Ologsson. “Our mission at Zero ASIC is to make ordering an ASIC as easy as possible. as easy as ordering catalog parts from an electronics distributor.”

The process will rely on a grid-like 3D interposer called eFabric, which improves the efficiency of die-to-die communication, as well as composability. It also supports the integration of processing blocks using 3D-linked eBrick chiplets.

The eBricks include a quad-core RISC-V Linux-compatible dual-issue processor, 5K LUT embedded FPGA and 3MB SRAM -3 TOPS machine learning accelerator.

These are ready-made designs that are accessible to everyone and can be assembled into a completed SiP using the service. Companies that design their own chips will then offer them to be physically manufactured.

The company says that using its service will lead to cost and energy savings of between ten and a hundred times, especially when you compare it to the process required to make today’s best processors.

The company says the chips designed using this process would be suitable for a variety of industries and use cases, including those facing supply chain and sustainability challenges. The company cites robotics, automotive safety, aerospace and defense, as well as 5G and 6G communications as suitable applications for these chips.

However, since they won’t be sampling until the third quarter of 2024, companies like Nvidia and Intel don’t have to worry yet that Zero ASIC’s products will erode their market share.