Audi makes ‘painful’ decision to close the Brussels EV factory as demand for electric cars decreases

Audi has announced it will close its Brussels factory at the end of February, in the latest blow to EV production.

The German manufacturer, part of the Volkswagen Group, has made the ‘painful’ decision after failed attempts to find a buyer for the car factory.

The factory will close on February 28, 2025 Brussels Times report that 3,000 jobs are now at risk.

It follows a series of cost-saving measures for the automotive sector by Volkswagen in Germany, where salaries have been cut, thousands of employees are at risk of being laid off and several factories are lined up for closure due to the slowdown in electric car sales.

The closure of the Audi Brussels site also raises questions about the future of one of Audi’s flagship electric cars, the Q8 e-tron, which is currently produced at the plant.

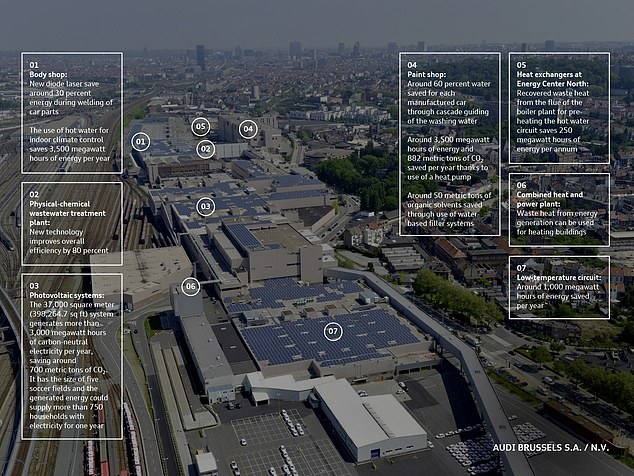

The 30,000 m² factory has been producing the Q8 e-tron and Q8 e-tron Sportback since 2022 and is the main producer of the models.

Audi’s decision to close its Brussels factory due to falling demand for electric vehicles puts the future of its Q8 e-Tron models at risk

The Brussels factory produced only 53,555 Q8 e-tron and Q8 e-tron Sportback cars in 2023, which is less than half of the factory’s entire production capacity

In July, Audi revealed it was considering “the early end of production” of its largest electric car, while shifting focus to its smaller electric SUVs such as the Q4 and Q6 e-trons.

The Brussels plant produced only 53,555 Q8 e-tron and Q8 e-tron Sportback cars in 2023, compared to the annual maximum capacity of 120,000 vehicles.

An Audi spokesperson told Auto Express: ‘Against the backdrop of the intended end of production of the Q8 e-tron model family on February 28, 2025 and the current supplier strikes at the Brussels site, we have introduced a temporary order freeze for introduced the Q8. e-tron.’

The 30,000 m² factory in Brussels has been producing the Q8 e-Tron and the Q8 e-Tron Sportback since 2022 and is the main producer of the models

Audi spokesman Peter D’hoore made the announcement of the factory closure last week after the company said no alternatives had been found to the worst-case scenario conclusion.

Gerd Walker, Audi AG board member and head of production, told Reuters: “The decision to close the Brussels plant is painful.

“Personally, this was the most difficult decision I have ever had to make in my professional career.”

The difficult move follows strikes at parent company Volkswagen’s factories after the manufacturer threatened to close three of its factories, but did not specify which factories would be at risk or how many jobs would be lost as a result.

While Volkswagen is still mulling the decision – which would be the first factory closures in its 87-year history – Audi has pulled the plug after efforts to sell the plant in recent months failed to produce a buyer.

Chinese EV maker Nio was reportedly in talks to buy it, but CEO William Li denied those rumors.

Gerd Walker, Audi AG board member and head of production, told Reuters the decision to close the Brussels plant is “painful”

The exact reason for the closure has not yet been confirmed, but it is likely a combination of ‘long-standing structural challenges’ at the site, as well as high delivery and shipping costs due to the location.

The proximity of the factory to the city center also makes restructuring too difficult.

Audi’s announcement comes against the backdrop of a slow uptake of electric vehicles on the continent, which the German brand says has led to a “global drop in customer orders in the electric luxury class.”

Several thousand employees of Europe’s largest carmaker Volkswagen AG gather during protests against pay increases at the site of VW’s largest factory in Wolfsburg, Germany, December 2

It is the first time in its 87-year history that the company has threatened to close factories in Germany (demonstration in Zwickau in photo)

Sales of VW cars have plummeted in Europe as demand stagnates and consumers return to gasoline.

Global sales fell by three percent in the first three months of the year, while gasoline engine sales rose by four percent.

Volkswagen’s decision to cut 30,000 jobs and implement a 10 percent pay cut has led to strikes at its factories in Wolfsburg, Hannover and Zwickau (VW’s electric-only factory).

The declining demand for electric vehicles and rising costs are being felt throughout Europe.

Stellantis – owner of Vauxhall – blamed the UK government’s Zero Emission Vehicle (ZEV) mandate for its plans to close the Luton factory in April 2025.

Vauxhall staff are currently holding a two-day protest and rally from Tuesday, December 17 to Wednesday, December 18 over Stellantis’ plans to close its profitable electric van factory in Luton, after unions said the proposal makes ‘no sense’ .

Sharon Graham, general secretary of car union Unite, said: ‘There has now been a right to call on (CEO) Carlos Tavares, whose counterproductive strategy of cutting Stellantis to the bone to artificially inflate profits has clearly failed.

“The opportunity now exists for Stellantis to avoid the unnecessary destruction of its Luton operations.”

Elsewhere, the boss of Ford’s UK arm has warned that the UK car industry is in crisis due to the overwhelming lack of demand for electric cars.

Nissan has also warned ministers that the ZEV mandate will cost thousands of automotive jobs in Britain.

Some links in this article may be affiliate links. If you click on it, we may earn a small commission. That helps us fund This Is Money and keep it free to use. We do not write articles to promote products. We do not allow a commercial relationship to compromise our editorial independence.